20% net energy improvement; CO2 emissions reduced by 43,000 tonnes.

In 2008 Barrick developed a Climate Change Standard that stated a requirement to improve energy and associated greenhouse gas (GHG) efficiency in operations globally. Barrick operates 26 mines world-wide, of which 19 currently are operating grinding circuits with 6 additional installations either in construction or planned. Ore grinding can account for 60% of a site’s electrical power load and more than 35% of the operation’s greenhouse gases (GHG) as measured in tonnes of CO2 equivalent. Initial observation of Barrick's grinding circuits indicated potential opportunities for improvement as both an economic and a GHG efficiency opportunity.

In order to address their Climate Change Standard, Barrick identified opportunities to reduce energy usage by reviewing the energy efficiency of their grinding circuits worldwide.

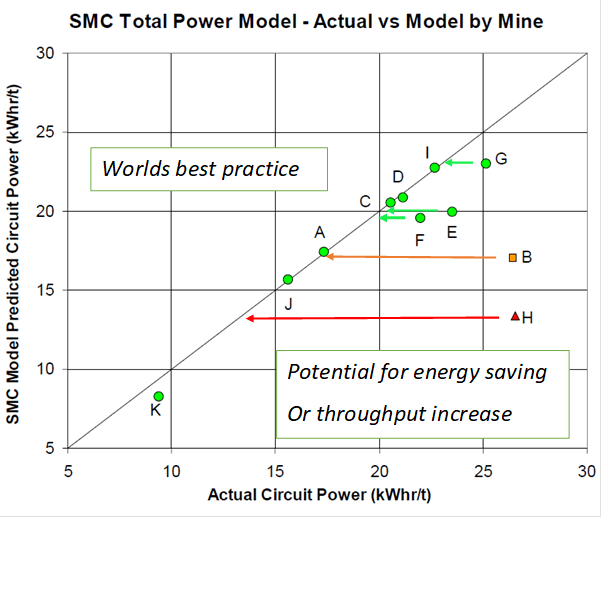

The SMC Test was instrumental in determining the potential for energy savings through the use of Morrell’s power-based equations, which determine the required amount of energy of comminution circuits. These equations require the results from SMC Tests on representative samples of the ore that a comminution circuit is processing. The equations then predict what the specific energy (kWh/t) of the circuit being studied should be consuming.If the circuit is consuming more energy than the equations predict it indicates that there is a potential that the circuit is using more energy than is necessary as well as the possible magnitude of the energy that could be saved. Further analyses are then carried out concerning the manner in which the comminution circuit is being run. These analyses often include simulations using JKSimMet to investigate more energy efficient ways of operating the various parts of the comminution circuit. The models used in these simulations also require the results from SMC Tests.

The combined result from improvements at 3 sites was a reduction of 43,000 tonnes of CO2 with a saving of $5 million in energy costs per annum, whilst at the same time comminution circuit throughput increases resulted in annual gold production climbing by 60,000 oz or the equivalent of additional revenues of US$90,000,000 per annum at current gold prices.

The approach taken in this project was developed in to a Global Mining Guideline called the "Morrell Method", and can be used by mining companies to benchmark and optimize the performance of their comminution circuits across operations globally.